Including a silkscreen improves the quality of PCB assembly and testing, as well as identification. After that, they use UV light on the ink.

SILKSCREEN PCB SOFTWARE

Computer-aided drawing (CAD) software is utilized to apply ink to the PCB. Acrylic inks and inkjet projectors are necessary for DLP. Direct Legend PrintingĭLP is more expensive than other methods. However, LPI uses more ink than other methods.

SILKSCREEN PCB MANUAL

This method gets better accuracy than manual screen printing can achieve. Once they do that, they put it under ultraviolet (UV) light for curing. The main difference is that LPI involves coating the laminate with epoxy. How technicians do LPI is extremely similar to the solder mask application. The LPI method is appropriate for screen printing when lines exceed 4 mil. After the PCB silkscreen ink is sent through the stencil to create the silkscreen print, the layer or laminate is put into a baking oven to cure. Manufacturers create the latter with nylon. This manual screen printing is done by way of a stencil with text and traces.

SILKSCREEN PCB REGISTRATION

This method of silkscreen application is useful when there are line widths higher than 0.007” or when there is a 0.005” registration tolerance. Silkscreen application is part of the PCB manufacturing process. These are manual screen printing, liquid photo imaging (LPI), and direct legend printing (DLP). There are three different methods used for applying a silkscreen to the PCB. Reference designators that facilitate finding parts.

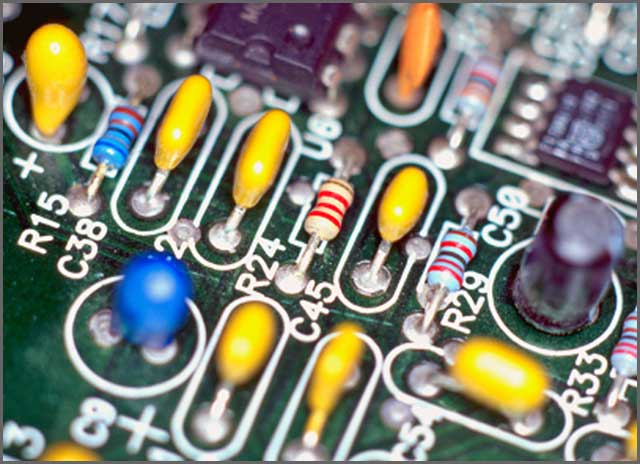

Silkscreen print helps you identify and understand: What Information Does a Silkscreen Provide?Ī silkscreen provides several kinds of useful information. This is key to ease of use, especially if you aren’t an expert. You can see where all the components are and should be positioned on the silkscreen PCB easily.This is useful when identifying polarity orientation and component type. You can use it as a reference indicator.You may see warning symbols as well as symbols indicating voltage and current.This is especially important when taking measurements and troubleshooting. Engineers and technicians can find the PCB’s test points more quickly and easily.What Is the Purpose of Using a Silkscreen Layer?Ī silkscreen’s purpose lies in its many benefits. These include a polyester screen that will be stretched over aluminum frames and spray developer, curing ovens and a laser photoplotter. The traditional method for creating a silkscreen involves certain materials. When a silkscreen is detailed meticulously, it can be invaluable for manufacturers and engineers. It is applied to the PCB, usually on its component side. Technicians create a silkscreen with non-conductive epoxy ink. You will pay an additional charge for a silk screen PCB. Silkscreen on a PCB will be applied to the PCB board only if you request it. PCBs don’t come with silkscreens automatically. It has print that labels the components of the PCB clearly.

3 What Information Does a Silkscreen Provide?Ī silkscreen is a layer added to a PCB.2 What Is the Purpose of Using a Silkscreen Layer?.

0 kommentar(er)

0 kommentar(er)